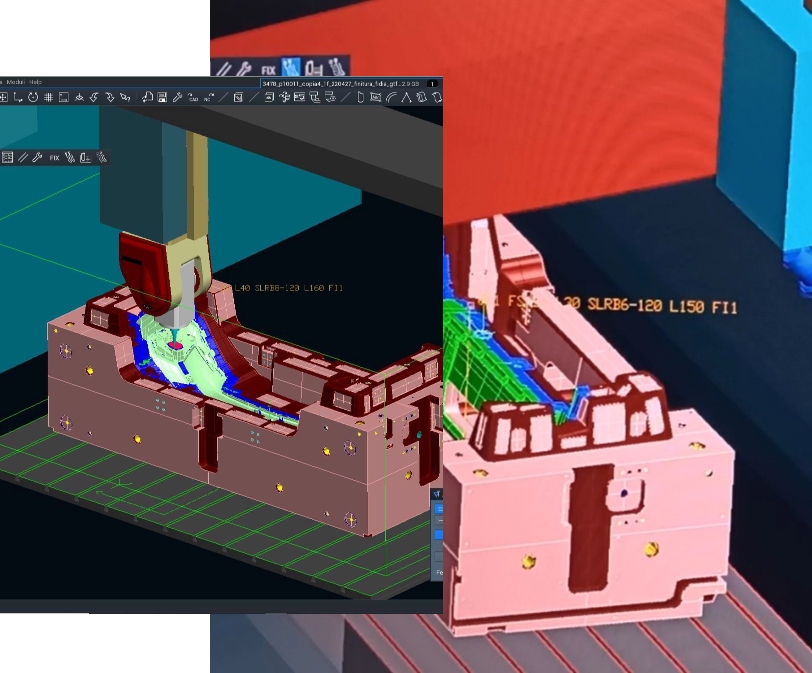

CAM / MILLING

Mechanical precision and artisanal craftsmanshipStrictness, speed, efficiency.

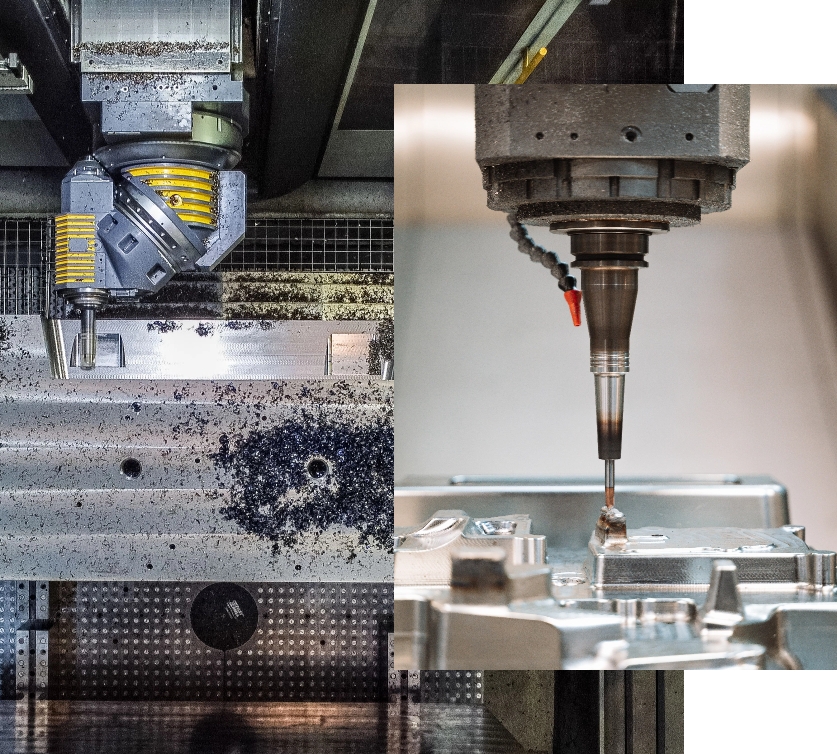

This is how we shape steel, supported by the best technologies and the expertise of our technical team. The production programming phase is carefully followed to ensure strict adherence to the agreed-upon processes and timelines with the customer.Shaping the material requires two elements that are both distinct and complementary: a production space equipped with state-of-the-art machinery and a highly qualified, experienced team.

In our facility, the main mechanical processes take place, starting with roughing the steel blocks to give the first shape to the mould, followed by semi-finishing, drilling, and erosion.

The meticulous milling and finishing operations represent a great added value in terms of efficiency for S&S, which, thanks to over 50 years of know-how and experience in the industry, ensures that its moulds not only meet the highest technological standards but also embody the quality and precision of artisanal craftsmanship that has always distinguished Made in Italy worldwide.

Each step of the mechanical processing is supervised by the Metrology department, which ensures compliance with the strictest quality standards for everything produced in-house and received from our partners: from raw materials to semi-finished products, from the finished mould to the whole testing process. The goal is to guarantee the best performance of the mould throughout its production cycle.

Each step of the mechanical processing is supervised by the Metrology department, which ensures compliance with the strictest quality standards for everything produced in-house and received from our partners: from raw materials to semi-finished products, from the finished mould to the whole testing process. The goal is to guarantee the best performance of the mould throughout its production cycle.

Other steps

01

Know-how and Co-design skills to bring your ideas to life

02

Mechanical precision and artisanal craftsmanship

03

Construction perfection is all about the details

04

The moment when our clients can experience their work firsthand