ENGINEERING

Know-how and Co-design skills to bring your ideas to lifeVision, design, and innovation.

To meet the needs of our partners, the first step is to create a high-performance project that perfectly blends design and cutting-edge technological performance.Constant investments in R&D have allowed S&S to establish a highly skilled design department, working closely with partners during the co-design phase, analysis, and feasibility studies. This collaboration ensures the achievement of the highest quality standards in the shortest time possible, all while maintaining a focus on cost efficiency.

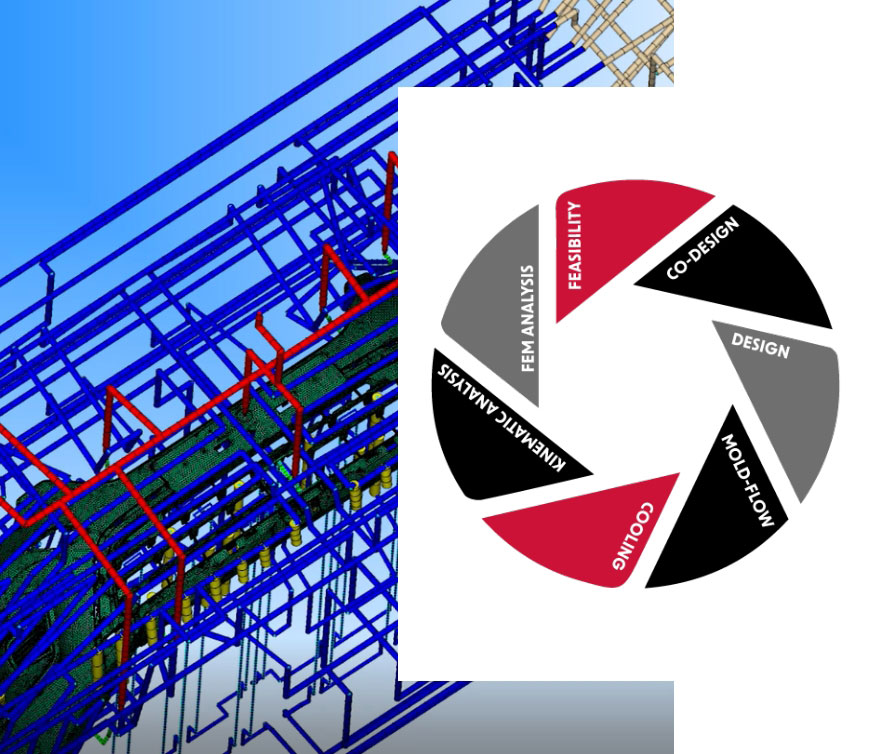

Our Services in Engineering and Co-design

Feasibility: Feasibility study based on the 3D design provided by the styling office.Co-design: Creation of a functional, aesthetically exclusive design that helps reduce production costs.

Design: We bring the mould and all its components to life to create a model that meets all the parameters of the moulding process.

Mould-flow: we simulate the moulding process through CFD simulation software. Carrying out these studies allows us to improve the polymer injection system, optimize the part, prevent filling problems and adjust process parameters.

Mould-Cooling: using the simulation, we verify and optimize mould cooling system to optimize its performance.

Kinematic Analysis: we analyse and simulate every movement to validate mould kinematics and to guarantee constant performance over time.

FEM Analysis: structural analysis to ensure strength, durability and performance

Other steps

01

Know-how and Co-design skills to bring your ideas to life

02

Mechanical precision and artisanal craftsmanship

03

Construction perfection is all about the details

04

The moment when our clients can experience their work firsthand